WZP-300 induction hardening machine induction annealing equipment industrial heating furnace

Product Description

Industrial heating furnace can be used for Induction hardening shaft, gear, wheel ,sprocket .

Annealing gear, stainless steel pot

heating steel rod, round square rod, flat bar

tube ,pipe inner wall hardening

Advantages of YONGDA induction hardening annealing equioment industerial heating furnace

1. The machine adopts IGBT modules (Siemens, Germany), high efficiency, energy saving.

2. Environmental. Almost no oxide layer, produced no exhaust, no waste-water is generated.

3. Heating fast and uniform.

4. A unique cooling circulation system, ensure that the equipment 24 hours of continuous work.

5. Easy installation, simple operation.

6. Safe and reliable. No high voltage, very safe for operating people.

7. Machine power can be adjust step-less.

8. It has complete self-protect functions: such as many types of alarm lamps: over-current, over-voltage, over hot, water shortage etc, can also control and protect itself.

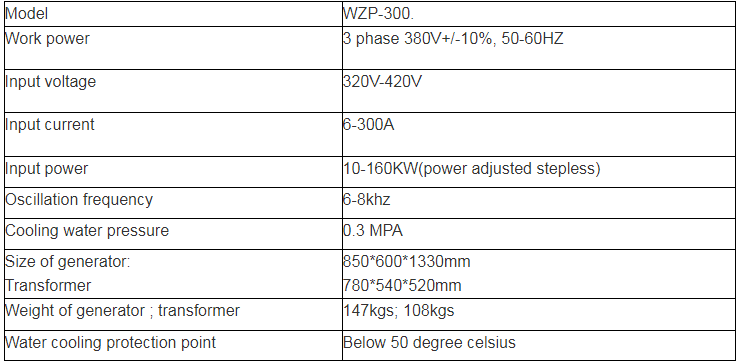

Technical parameters of WZP-300 industrial heating furnace

WZP-300A/160kw induction heating furnace photo

Customized frequency high frequency 15-30KHZ, hardening depth 1-4mm

or Medium frequency 6-8KHZ,hardening depth 4-6mm

CNC heat treatment quenching/hardening machine tool

shaft move up and down

transformer move up and down

work piece and hardening transformer, which weight is lighter, design which part move lifting

The CNC quenching machine tool has the following features:

1, the machine uses PC-industrial digital control systems, high performance, debug and easy to use, to the greatest degree of quenching the workpiece to meet the complex needs.

2, the machine can achieve quenching mode: continuous scan quenching, and quenching, sub-continuous scanning quenching (by the level of sub-setting, no limit switch, the same below), while sub-quenching.

3, this machine is suitable for the typical artifacts (in the appropriate size range) axis: a variety of shaft, step shaft, gear shaft, cam shaft, axle, the cylindrical disk-type parts, end so on.

4, the machine control system for reserve electrical heating and cooling water quenching control interface. According to the process of quenching process and the need to control the cooling process.

5, low running costs. Just run the workpiece drive motor 250W, machine power consumption less than one-fifth of machinery and equipment.

6, the fuselage structure by profile, low cost, light weight, economical and practical.

7, easy maintenance, low failure rate, no leakage.

8 high degree of automation and production efficiency.

9, rail uses linear bearings, high precision, small friction, long life.

10, with heavy equipment through the sprocket, chain balance the weight.

Electric Industrial heating furnace mainly used for forging,hardening, annealing, tempering, brazing, melting for many kinds of metal materials, such as auto parts workpieces, pipes, tubes, wires, rebars, motorcycle parts, camshaft, crankshaft, gear, axles, sprockets, etc. According to specifications of your workpiece requirement, we will offer you the best suitable machine.

1, forging, hot forming

A, all kinds of standard parts, fasteners, machinery parts, hardware tools, straight shank twist hot upsetting, hot.

B, metal heat annealing. Such as: tensile steel tube, pipe, smashed head; wire, heating wire nail; stainless steel annealed, rose type.

2, heat treatment,hardening,quenching

Various types of hardware, electrical, hydraulic, pneumatic components, automobiles, and motorcycle parts and other mechanical parts of the surface of the metal, bore, in part or in whole quenching. Such as: hammer, knife, scissors, pliers and various types of shafts, cams, sprockets, gears, valves, ball pin, large-scale Machine Tool, ductile iron quenching.

3, brazing,welding

Various types of carbide blades, turning, milling, planer, reamer, diamond saw blade, saw welding; grinding, drilling, cutting welding; brass, copper, stainless steel and other metal materials, the composite bottom of the pot Welding.

4, metal melting: melting gold, silver and copper.

5, the other heated areas

Plastic pipe, cable, wire heating film; food, beverage, pharmaceutical industry uses aluminum foil.

1. energy efficient

Up to 98% thermal efficiency under the same conditions, resistive heating method than saving up to 75% or more, shorter warm-6min.

2. reliable operation

Intelligent multi-loop control system and perfect protection system to ensure long-term safe and reliable operation of equipment.

3. lower production costs

Heating part of the structure with cables, heating cable itself does not generate heat, long service life. Resistive heating to avoid regular maintenance and periodic replacement of needed heating coil, the latter almost no maintenance costs.

4. improve the working environment

Some of the heat dissipation of less heat, the surface can touch and improve the environmental conditions of the production site.

5. intelligent multi-temperature control

Victoria Ellis electromagnetic energy heating devices use liquid crystal display real-time temperature and set temperature range.Built-in chip intelligently controls heating rate and output power, according to the actual situation of flexible adjustment of raw plant.

6. the high temperature heating

Resistive heating power density is low, the heat quickly to the outer space, and generally difficult heated to above 400 ℃. The energy-efficient way, reactive power density, can be heated to temperatures above 600 ℃.

1.First, good energy saving effect: compared to the original resistance wire heating cycle saving effect in more than 30%, relatively different raw materials, production of different products, energy-saving effect change. But in the current energy-saving products have been used up to 80% efficiency

2.Second, good environmental effect: the production environment can significantly reduce the temperature.

3.Third, long service life: continuous operation temperature of the heating cycle is only about 100 ° C, there is no problem to replace the heating cycle, relative to the original resistance wire heating to reduce the secondary input.

4.Fourth, improve product yield: As the heat efficiency of the product, with uniform heating, can significantly reduce the heating time and increase product yield.

1.First, the heat loss is too large: the current heating method used by most companies is around the system by the resistance wire, heating both sides inside and outside the ring will heat, heat conduction inside the cylinder, while most of the heat lost to the outside air , causing a loss of energy waste.

2.Second, the environmental temperature increases: a lot of loss due to heat, ambient temperature, especially in summer a great impact on the production environment, on-site temperatures over 45 ° C, some companies had to lower the temperature by air-conditioning, which in turn causes energy secondary waste.

3.Third, life is short, large maintenance : As a result of the resistance wire heating, the heating temperature up to about 300 ° C, under high temperature aging resistance wire easy to blow, electric lap average life of about half a year, so maintenance work relatively large.

1.Heating fast: this is the heating rate of less than 1 second (speed adjustable speed control)

2.Heating wide: wide range of metal parts can be heated (according to the different shape of the workpiece replacement of removable induction loop)

3.Easy installation: connect the power, induction loop and out of the water can be used; small size, light weight, easy to use

4.Simple operation: a few minutes to learn

5.Start fast: you can start with water after the heating power

6.Low power consumption: high-frequency device than the old-fashioned tube about 70% energy saving, the smaller the power consumption of the smaller parts

7.Good effect: the heating is very uniform (also by regulating the induction coil density, so that all parts of the workpiece to obtain their desired temperature), heating up fast, less oxide layer after annealing without waste

8.Adjustable power: The Promise adjust the output power

9.Protection all: with over voltage, over current, overheating, lack of water and other alarm indicator, and automatic control and protection

10. small size, light weight, simple installation, easy to operate;

11. high efficiency, saving energy obviously,save 60% energy than traditional high frequency tube equipment, and save 20% energy than KGPS SCR IF induction heating power.

12. secure, reliable, non-million-volt high-pressure, very safe for the operator;

13. the frequency bandwidth to meet the different parts of the heating before forging, heat treatment, brazing, etc.;

14. a unique cooling circulation system, ensure that the equipment 24 hours of continuous work.